In the process of internationalization and modernization, Zhongtian Chengda Mold attaches great importance to the standardization and normalization of production processes and quality management. To this end, Tianchengda has long adhered to the quality policy and purpose of "precision manufacturing, providing customers with competitive products; continuous improvement, providing customers with high-quality and satisfactory services". Full participation, comprehensive quality control, and effective implementation of ISO9001 international quality system standards. And conduct strict evaluation and assessment of all incoming suppliers to ensure that all incoming materials meet the processing standards.

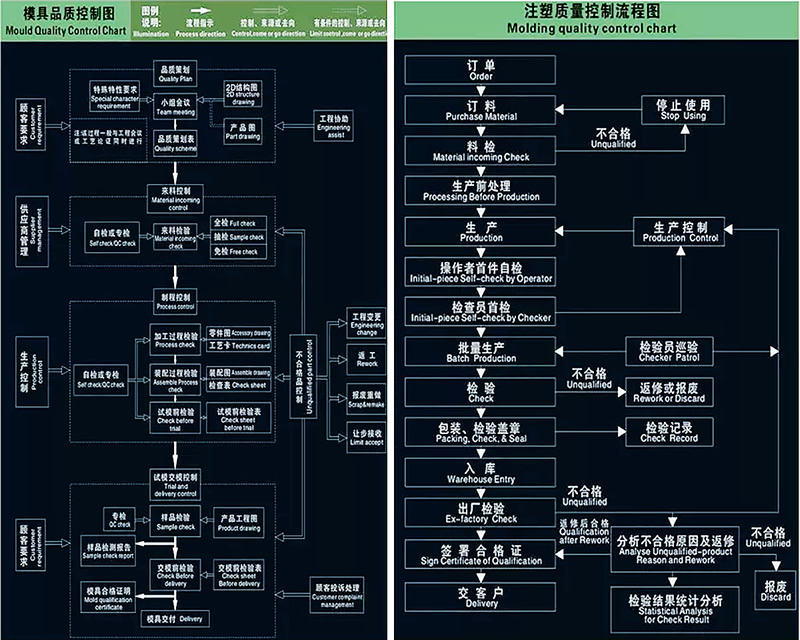

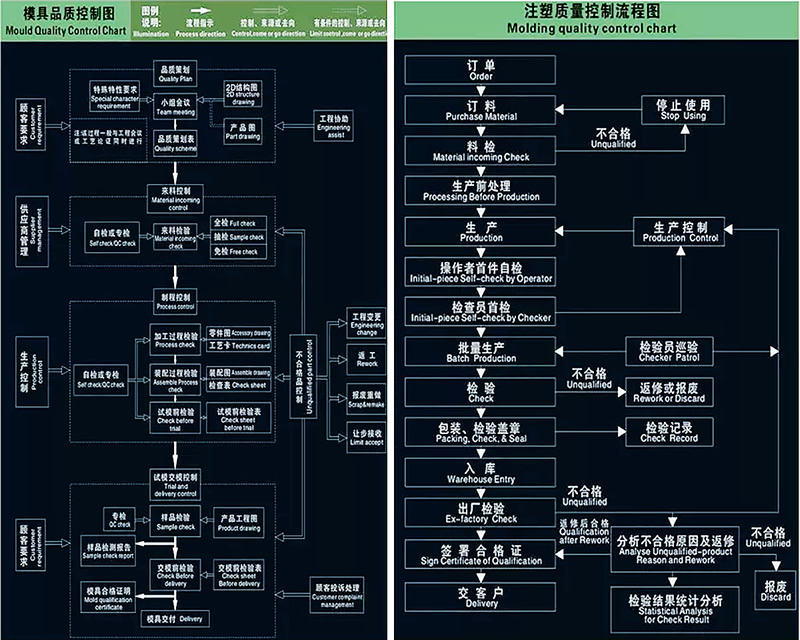

At present, Tianchengda has established long-term cooperative relationships with many well-known suppliers, including LKM YUDO、HUSKY、MISUMI、HASCO、DME, To ensure the quality of the product before processing. Tiancheng Daxing is proficient in mold design standards such as HASCO and DME. Each processing procedure and process flow is made according to customer requirements with "standard operation instructions" and "product quality inspection standards". The entire production and processing process adopts multiple scientific and strict inspection procedures and quality control points such as IQC, IPQC, FQC, OQC, etc., and with the help of advanced testing instruments such as coordinate measuring instruments, image measuring instruments, projectors, etc., Tiancheng Daxing provides customers with the most excellent quality assurance in all aspects under the guidance of scientific process flow.